TECHNICAL SUPPORT

WE MAKE PPE EASIER !

Please find below our selection guides by product category.

In case of doubt, do not hesitate to contact us.

CRITERIA OF CHOICE

Choosing a glove is a trade-off between the level of protection required, as established during a workplace analysis, the required level of comfort and - more importantly than just the cost - its value in use (dutability, productivity).

Our catalogue has been designed to help you find the most suitable glove for the protection you require. We suggest several steps to establish the different criteria for selecting the best glove.

TO IDENTIFY AND CLASSIFY POTENTIAL RISKS

DEFINE THE GLOVE THAT BEST SUITS YOUR NEEDS IN TERMS OF:

EXPECTED LEVEL OF PROTECTION:

In accordance with performed tasks.

TYPE OF WORKS:

Precision work or general & heavy duty work. This will define the level of dexterity.

ENVIRONMENT :

Dry, slightly oily, oily or wet. This will define the chemical nature of the coating

EXPECTED COMFORT LEVEL:

May depend upon the wear time (short-term, intermittent, continuous), the expected breathability or flexibility. This will improve productivity.

CHOOSE THE MOST APPROPRIATE PRODUCT WITH THE HELP OF TECHNICAL DATA WHICH SHOWS THE APPLICATIONS AND BENEFITS OF EACH GLOVE

GLOVE FEATURES

TYPES OF COATING

NATURE OF COATING

THE EXTERIOR FINISH

THE INTERIOR FINISH

DIFFERENT STYLES OF CUFFS: WRIST FINISH

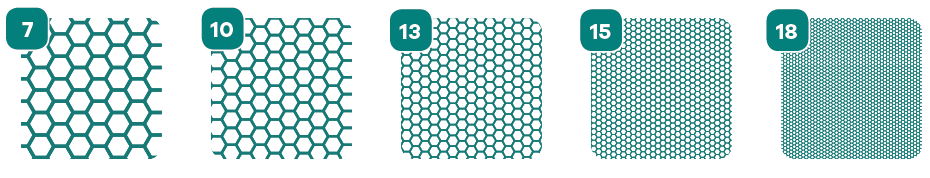

WHAT IS THE GAUGE?

A unit of measurement corresponding to the thickness of the stitch. The thinner the stitch, the greater the dexterity of the glove.

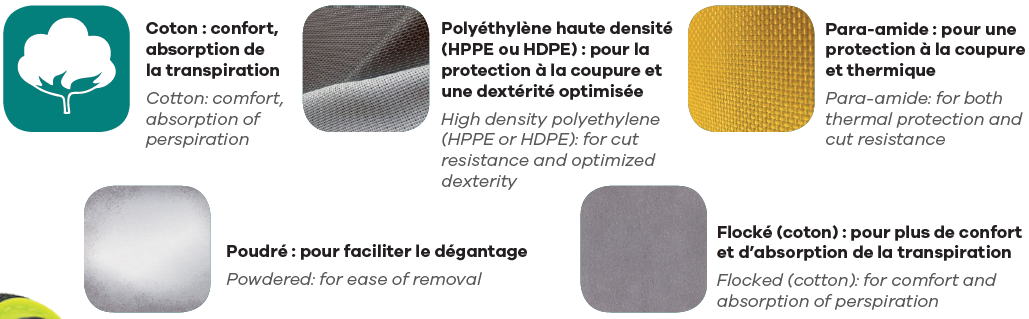

MATERIAL

PROTECTION

PVC

NITRILE

NEOPRENE

LATEX

VINYL

+

- Excellent resistance to abrasion

- Good resistance to aqueous solutions (acid, base,…)

- Good grip

- High elasticity

- Good mecanical Resistance

- High resistance to oils, fuel and some organic solvent

- No allergy

- Wide chemical protection

- Good mechanical resistance

- Good thermal resistance

- Sustainable

- Very high elasticity

- Flexibility

- Durability

- Comfort and manoeuvrability

- Good grip

- Resistance to cut and puncture

- No allergy

- Good resistance to oxidising acids

-

- Sensitive to UV rays

- Sensitive Low temperature

- Sensitive Organic solvent

- Low resistance to flame

- Low grip with wet surface

- Reduced resistance to hydrocarbons (oils or fuel)

- May cause allergic reactions

- Low resistance to flame

- Low resistance to hydrocarbon and organic solven

- Moderate mechanical resistance

AND ALSO...

The sizing, the thickness, the length and the shape (ambidextrous or anatomical) are the elements that define a glove.

SELECTION CRITERIA

Foot injuries account for approximately 7% of work-related accidents:

- Trauma such as punctures, crushing and laceration.

Injuries resulting from slips, false movements and falls.

It is impossible to stand, walk or run without feet. It is one of the most important mechanics of our body. They support its weight and absorb shocks on contact with the ground. It is therefore essential to ensure their protection and comfort.

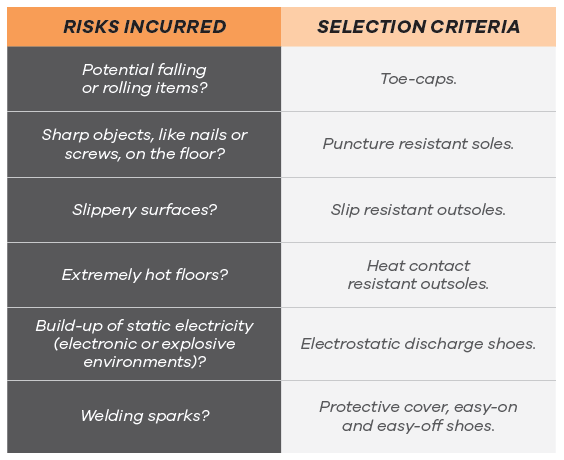

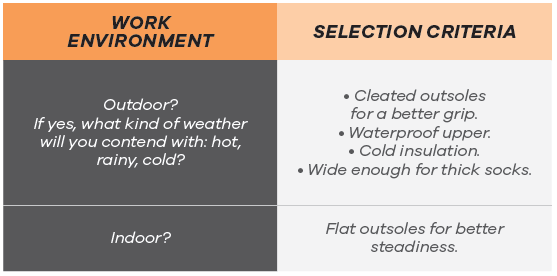

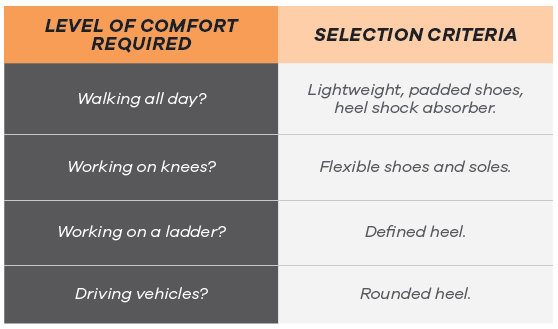

Appropriate safety footwear must be chosen based on three main criteria:

- Risks incurred

- Work environment

- Level of comfort required

TECHNOLOGIES AND MATERIALS

Coverguard® safety shoes and boots are made from quality technologies and materials, with a modern design.

Designed to protect your feet from potential hazards at your work site, the Coverguard® range also ensures you the comfort you need according to your working environment, indoor and/or outdoor in every season.

All the products of the Coverguard® range meet the requirements specified by EN ISO 20345:2011 standard.

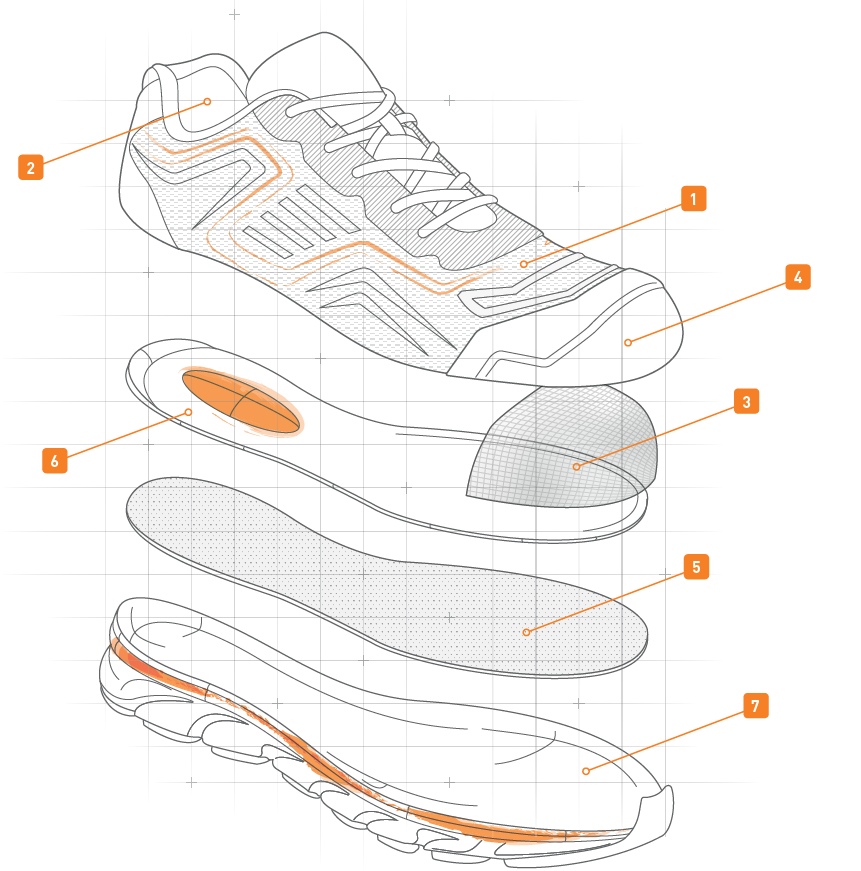

UPPER

Upper is the top part of the footwear that covers and protects the foot. It is made from natural materials like leather and/or synthetics ones.

LINING

The lining is the material inside the shoe in direct contact with the foot. It protects the inside seams and lengthens the shoe’s lifespan. Made from various textiles, the lining also ensures breathability and comfort for the wearer.

TOE-CAP

The toe-cap is located at the front of the shoe, between upper and lining. It is used to protect the toes from potential impacts and compressions. It can be metallic (steel or aluminum) or composite (carbon fiber, fiberglass, plastic).

SCUFF-CAP

Scuff-caps when available are located at the front and the back of the shoe or boot. By reinforcing the wear and tear upper resistance, scuff-caps allow longer footwear’s lifespan. Leather, stark®, TPU or KPU (PU of different thicknesses) are used for scuff-caps.

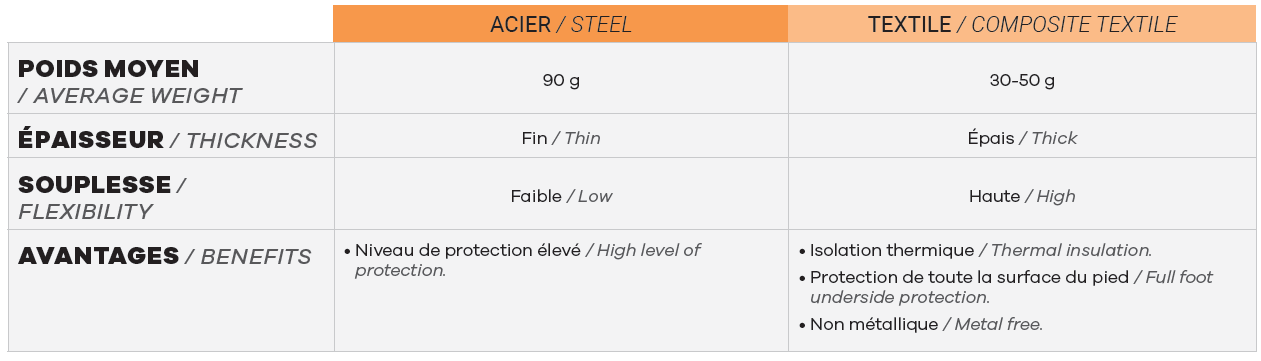

PUNCTURE RESISTANT SOLE

Made of steel or composite textile, the puncture resistant sole is located under the insole. It is manufactured in such manner that it can’t be removed without seriously damaging the safety footwear.

INSOLE

Removable and flexible, insoles are a complement of hygiene, climate comfort and shock absorption. HI-POLY foam, EVA, silicone insert or wood fiber contribute to the technicality of these components, essential to the comfort of the wearer.

OUTSOLE

The outsole can be made from one single sole (mono density) or two (double density): the outsole in contact with the ground and the midsole located between the outsole and the puncture resistant sole.

Those soles can be either cemented, upper and soles are glued together, or injected, the soles are molded on the upper by injection.

TEXTILES

FIBRES

For a material to be textile, it must allow the realization of yarns.

The textile fibres used in the composition of the clothes of the Coverguard® range fall into two categories: Natural Fibres of plant origin such as Cotton and Synthetic Fibres, or chemically created non-cellulose polymers such as Polyester, Polyamide, Acrylic or Elastane.

FABRICS

GRAPHENE

WHAT IS IT?

Graphene takes its name from graphite, a natural mineral, of which it is a derivative (example: pencil leads).

It is the thinnest layer of graphite imaginable: this totally invisible 2D material is made up of a single layer of carbon atoms linked in the

form of hexagons (vs. several layers for graphite).

Graphene is the lightest, strongest and most conductive material identified to date.

IN WHICH FORMS?

Graphene is mainly used in the form of inks in the textile industry, as in the membrane coating of our PYTHON model: only a few atoms can give it its properties.

FEATURES:

- Thermal conductor/thermo-regulator (up to 5 300 W m−1 K−1 ) : Distributes heat evenly through the bonding of its atoms.

- Hot weather: It dissipates body heat according to the environment and physical activity

- Cold weather: it transmits heat from hot areas to colder areas

- The closer the graphene is to the skin, the better it will be at regulating your temperature (+/- 2°C on average).

- Bacteriostatic:it reduces the formation of odors due to perspiration by stopping the proliferation of bacteria

- Resistant:200 times more resistant than steel while being ultra flexible (the atoms are strongly linked together)

- Lightweight:Adds properties to the garment without weighing it down. A few grams are enough!

- Electrical conductor:possibility of developing intelligent textiles (e.g. 3D printing of batteries with graphene ink)

- Antistatic:graphene being conductive it allows to dissipate electrostatic charges

- Non-polluting:can produce energy by itself naturally (without additives)

COATING

WHAT IS COATING ?

Coating is a process of applying a coating (plastic material) to the surface of a fabric to give it characteristics that are not intrinsic to it.

- It is called a coating layer

- It has a barrier role

Characteristics :

- Fixes the fibres : greater resistance to abrasion and ageing

- Allows for water repellency, waterproofing, etc.

- Weather protection

- Thermal insulation: hot or cold

Type of coating :

- PVC : Flexibility, UV resistance / More plastic effect

- PU : Good tensile and tear strength / More expensive

SOFTSHELL

A softshell is designed to balance breathability and waterproofing against the elements.

3 types of Softshell :

- 3 layers:outer layer + 1 waterproof and breathable laminated membrane + 1 inner layer laminated with fleece for warmth. E.g. Fresh environment

- 2,5 layers:1 outer layer + 1 waterproof and breathable laminated membrane + 1 protective film of the membrane E.g.: Warm environment/ mid-season

- 2 layers:1 outer layer + 1 waterproof and breathable laminated membrane + 1 suspended lining for comfort (mesh) E.g.: Warm environment/ mid-season

SORONA® TECHNOLOGY

SORONA® : A GREAT ALTERNATIVE TO DOWN

DuPont™ Sorona® is an innovative, partially plant-based polymer. This technology is chosen to create exceptional insulation products with long-lasting performance.

In comparing insulation made with Sorona® to insulation made with premium, branded polyester, Sorona® outperforms in many key categories :

- Improved ability to retain heat in both dry and wet atmosphere: +7% Optimization of the weight/heat ratio

- Lighter – Improved fill power: +36%

- Less insulation is needed to provide the same warmth

- Less bulky

- Compression and recovery:

- Higher compression ratio: +8% (65% vs 60%)

- Recovery ratio= 96%

- greater movement and flexibility

- Quick drying : Excellent moisture wicking

- Renewable sourced : 37% (annually renewable plant-based

ingredients by weight

37.5® TECHNOLOGY

INCREASES PERFORMANCE: USE LESS ENERGY TO DO THE SAME AMOUNT OF WORK

- Natural: Volcanic minerals integrated into the fiber

- Permanent: The active 37.5® particles never wash out

- Thermoregulating: Helps maintain the ideal core body temperature of 37.5°C

- Comfortable: Removes sweat in the vapor stage

- Helps stabilize humidity levels at a comfortable 37,5%

- Traps odors and releases them when laundered

- Uses your body’s own infrared energy to warm you when you are cold

FIND THE APPROPRIATE RESPIRATORY PROTECTION FOR THE RIGHT USE

RESPIRATORY RISKS ASSESSMENT

mending Directive 2004/37/EC, Directive (EU) 2019/983, which comes into force in July 2021 , provides for a lowering of the exposure limit values for certain carcinogens or mutagens at work. It sets out a framework of general principles to enable Member States to apply the minimum requirements uniformly In addition, Directive 2004/37/EC does not prevent Member States from applying additional measures, such as a biological limit value.

The European Standard EN 529:2005 shows how to select the correct breathing equipments based on the risk assessment. This standard indicates the “protection factor” which is by definition the parameter that expresses the ratio between the concentration of the contaminant in the environment and its concentration inside the breathing equipment. An important distinction concerns the nominal protection

factor (NPF) and the assigned protection factor (APF).

The nominal protection factor (NPF) is a number derived from the maximum percentage of total loss (towards the inside of the breathing equipment) allowed by European standards.

The assigned protection factor (APF) is the level of respiratory protection that one can realistically expect in the workplace by 95% of the PPE users.

Furthermore , an important reference for choosing the breathing equipment is the Threshold Limit Value (TLV), or rather the “exposure limit value”, which indicates the environmental concentrations of airborne chemicals below which most workers can remain repeatedly exposed to day after day for their working life without any negative effect on their health.

STANDARDS

MARKING DESCRIPTION

OUR NON REUSABLE MASKS (NR)

All of our non reusable masks are allergy tested and cannot be used for use in environments where the oxygen concentration is below 17% Vol.

They are offering following benefits based on user expectations

PERFORMANCE

WEARING COMFORT

EASE OF USE

WHAT FFP PROTECTION MATCHES WITH YOUR USE?

OUR REUSABLE MARKS (R)

Use only when O2 > 17%

PERFORMANCE LEVEL OF GAS FILTERS

To wear a face mask like a full face or a half face mask, it is necessary to make sure that the sealing surface is completely continuous to the face. Men must be correctly shaved and any interposition of hair, beard, or glasses temples must be avoided (otherwise the assigned protection factor will be reduced).

WHEN PERFORMANCE MATTERS FOR USER COMFORT

The most advanced Coverguard respiratory protections are offering functions that answer the most stringent user’s expectations.

ERGONOMIC DESIGN

EASE OF USE AND COMFORT

VISUAL COMFORT (FULL FACE MASKS)

FILTERS OF MASKS WITH CARTRIDGES

GAS FILTERS

Protect from gases and toxic vapors

LONGEVITY TEST OF A GAS FILTER

The longevity of a gas filter is measured by outputting trial gas up to 30 L/min, it means that the volume of air an average-build person breathes per minute, while doing an average-tough work. The longevity can also roughly be calculated bringing the concentration in-site with the minimum penetration time that is required for one type of filter.

ANTI-GAS FILTER LONGEVITY CALCULATION

AREA OF USE

A

Gases and vapors of organic compounds at boiling point > 65 °C.

Examples of specific hydrocarbons: toluene, benzene, xylene, styrene, turpentine, cyclohexane, carbon tetrachloride, trichloroethylene.

Some solvents are often used in the form of mixtures, for instance solvents from benzene, mineral essence, mineral turpentine, white spirit, naphtha solvent.

Other organic compounds: Dimethylformamide, phenol, furfuryl alcohol, diacetone alcohol. As well as some raw materials raw materials and plastic additives, such as phthalates, phenolic resins, epoxidic plastics and polychlorobiphenyls in the form of PCB isomers.

AX

Gases and vapours of organic compounds at boiling point < 65 °C

B

Inorganic gases and vapours

For exemple: sulphide dioxide, chlorine, hydrogen sulphide (H2S), hydrogen cyanide (HCN), hydrochloric gas (HCI), cyanide compounds, phosphorus and phosphoric acid.

E

Organic acids, acid gases and in general gaseous acids, nitric acid, propionic acid, formic acid.

K

Ammonia and its organic derivatives organic amino such as methylamine, ethylamine, ethylenediamine, diethylamide.

P

Particles, solid and liquid aerosols

HG

Mercury

NO

Nitrous vapors and vitrogen dioxide

CO

Carbon monoxide

FILTERS OF MASKS WITH CARTRIDGES

PARTICLE FILTERS

Protect from solid and liquid particles such as dust, smoke, welding smoke, mist, microorganism and radioactive particles.

- The filter does not wear out, but it gets blocked because of the particles and humidity that result from the increased resistance to respiration.

- Against the radioactive matters and microorganisms, a particle filter should be used only once.

- A particle filter must be changed when breathing becomes painful.

PARTICLE FILTERS

- Dust :solid particles transported by air and generated during the treatment of organic and inorganic matters. They can be composed of mineral, coal, wood or cereals such as diverse fibres (asbestos, silicate, fibreglass, etc…).

- Smocking gases:metallic particles generated by the cooling of an evaporated metal and its oxidation when in contact with the oxygen in the air. Smoking gases from lead oxide, for instance, are produced from lead melting. Ferric oxide gases are produced while soldering.

- Smokes:thin particles of coal and soot that integrate liquid droplets.

- Fogs:droplets transported by air, made up of a fluid scattering in the air, in the form of thin particles. Examples: oil fogs caused by metal machining, at the moment of cutting or grinding.

- Micro-organisms :for instance, bacteria, virus, spores.

- Radioactive particles :are produced by radiation.

COMBINED FILTERS

Combined filters stop both gases and vapors, as well as particles. First, the air crosses the elements that filter particles, then those that absorb gases. The filtering element stops the spread particles such as paint droplets.

Liquids spraying requires the use of combined filters.

WHEN PERFORMANCE MATTERS FOR USER COMFORT

The most advanced Coverguard eye protections are offering functions that answer the most stringent user's expectations

VISUAL COMFORT

ANATOMICAL FIT

STABILITY FOR A LONG WEARING TIME

HOW TO IDENTIFY THE LEVEL OF PROTECTION AND PERFORMANCE?

MARKING DESCRIPTION

Coverguard eye protections claim an optical class 1 suitable for permanent use.

MANDATORY MARKING

OPTIONAL MARKING

MARKING DEFINED ACCORDING TO THE USE

FIND THE RECOMMENDED HEARING PROTECTION THANKS TO THE LEVEL OF NOISE

THE NOISE INTENSITY DOUBLES EVERY 3 DECIBEL

FIND THE APPROPRIATE HEARING PROTECTION

Following parameters have to be considered:

- Identification of the nature of noise: stable, fluctuating, intermittent , pulse

- Measurement of the noise at workplace: Intensity (dB) and volume (Hz)

- Definition of the exposure time

- Calculation of the reduction level needed

Overprotection would cut the operator from its environment.

EMPLOYER'S DUTIES

In the workplace, the noise exposure limit values , which must not be exceeded, principally pertains to a daily or weekly exposure of 87 decibels (dB), taking into account any attenuation from hearing protection.

The exposure action values , the decibel level at which an employer must take certain actions, are set at a daily or weekly exposure of 80 dB (lower value) and 85 dB (upper value).

MINIMUM REQUIREMENT RELATIVE TO NOISE PROTECTION AT WORKPLACE

dB(A) = It is an A weighted decibel which is a unit of sound pressure level to measure environmental noise. Sound level meters are programmed to measure dBA, with «A» being a factor applied to reflect how the human ear would hear and interpret the sound being measured.

MARKING DESCRIPTION

HOW TO READ ATTENUATION INDEX AND VALUES

GET A HIGHER HEARING PROTECTION LEVEL WITH DOUBLE PROTECTIONS

Wearing a double hearing protection (earmuffs associated with earplugs) can be made necessary for particularly noisy works (from 120 dB). Studies have shown that the attenuation made by such combined protection was less than the sum of the attenuations provided by each one. This is explained by the mechanical acoustic coupling which exists between the two devices but also, more particularly for high frequencies, by an upper limit due to the passage of sound through bone conduction and which in some ways bypasses the protection, as efficient as it might be. The maximum attenuation level obtained during the tests of combining earmuffs and earplugs is around 40 dB.

SPECIFIC APPLICATIONS TO THE FOOD INDUSTRY

People working in food industry have special needs :

- Good hearing protection.

- Earplugs can be tracked if dropped in food preparations.

The earplugs 30210, 30211 and 30212 have a stainless steel ball diameter 2.75 mm) inside the stem. It allows trailing the earplug with a metal detector. The earplugs are blue, the only colour that cannot be found in food.

HOW TO CHOOSE THE APPROPRIATE SKULL PROTECTION?

Indoor work

- Impact against a hard immobile object which may cause lacerations, superficial injuries or stunting

Outdoor work

- Impact against a hard immobile object which may cause lacerations, superficial injuries or stunting

- Falling objects or loads in motion or suspension

BEST PRACTICES REMINDER

- Prefer good fitting and balance on the head rather than the real weight.

- Favor a headgear in textile rather than in plastic which conducts temperature effects.

- Always control the use-by-date of your helmet.

Any protection which has been shocked MUST be replaced immediately, as it will loose its efficacy.

STANDARDS REQUIREMENTS FOR SKULL PROTECTION

DISTINCTIVE PERFORMANCES FOR SPECIFIC USES

MATERIAL GUIDE

SPUNBONDED POLYPROPYLENE OR SPP

In this process, polypropylene resin granules are melted and then extracted through channels to obtain continuous filaments that are cooled and then randomly deposited on a receiving belt to form a uniform textile web.

These fibres are assembled by a combination of entanglement and thermo-welding (without the addition of any chemicals).

This Spunbonded process has the advantage of giving nonwovens high flexibility, tensile strength and breathability.

SPUNBOND MELT-BLOWN SPUNBOND OR SMS

Spunbond Melt-blown Spunbond or SMS is a tri-laminated textile composed of a layer of non-woven polypropylene (Spunbond Polypropylene or SPP), a layer of thermally welded polypropylene (Polypropylene Melt-blown) and a layer of nonwoven polypropylene (Spunbond Polypropylene).

The MELT-BLOWN technique consists of blowing hot air onto a molten thermoplastic resin that has been extruded through a linear die containing hundreds of small holes to form a selfadhesive, very thin-fibre non-woven strip. Its main characteristic is that it is an extremely thin fibre. As a result, this material is often used as a filter for air, liquids and particles.

When the MELT-BLOWN is superimposed on the SPUNBOND to form the SMS, the functionalities of each are combined, thus allowing a wider range of applications. Indeed,the combination of these 2 materials makes it possible to combine the characteristics

and compensate for the weaknesses of each (example: limited mechanical resistance of MELT-BLOWN).

SMS has excellent physical properties as well as barrier qualities against solid particles and chemical splashes while maintaining good breathability.

Microporous

MICROPOROUS is a textile composed of a layer of SPUNBOND POLYPROPYLENE covered with a microporous film laminated in polyethylene.

This process combines maximum breathability, comfort and a high level of chemical, biological and particle protection.Resistant textile, antistatic and lint-free treatment.

DUPONT™ TYVEK®

DuPont™ Tyvek® is a non-woven material manufactured exclusively by DuPont. It consists of pure high-density polyethylene filaments randomly arranged and compressed to form a versatile textile that is extremely tear-resistant, very lightweight and soft. It is permeable to air and water vapour but repels water-based liquids and aerosols. It forms an excellent protective barrier against fine particles and fibres.

It produces very little lint and also has an antistatic treatment.

SEAMS TECHNOLOGY

STITCHED

This technique provides robust mechanical strength of the seams while providing protection against light

splashes and dry particles.

STITCHED & TAPED

The internal seams are covered with a heat-sealed strip for optimal sealing against very fine dust, liquids in the form of mist and intense liquid projections.

WORK AT HEIGHT HIERARCHY OF CONTROLS

When we talk about Fall Protection, the image that often comes to mind is a worker using a full body harness, ie a Personal Fall Arrest System (PFAS). This is actually the last method to consider when you plan work at height.

Your first step should be trying to eliminate the fall hazard altogether.

AVOID work at height – (also called engineering out the hazard) meaning working as much as possible from the ground, using extending tools instead of a ladder, lowering something to ground level before repairing it, or for example using drones to get high vantage points.

This can require modifying the work process or work area to eliminate the need to work at height.

PREVENT a fall using Collective Protection Equipment (PCE) collective fall prevention systems such as guardrails, handrails, ladder cages, mobile elevating work platforms (MEWP)...

PREVENT a fall using Individual Protection Equipmentfall restraint systems, to prevent people getting close to an unprotected area.

The logic of the hierarchy of controls favours permanent rather than temporary equipment in collective protection. Similarly, CPE take precedence over PPE.

MINIMIZE consequences of a fall (Fall Arrest)– with a Personnal Fall Arrest Systems using a harness, energy absorbing lanyard and anchor point to minimise the risks and consequencs of a fall (especially the arresting force).

Fall arrest equipment will not prevent a fall from occurring and Personnal Fall Arrest systems are therefore the least preferred methods of working at height.

They should be used in situations where it is not practicable to arrange for the work to be done from a more suited surface, such as fixed or temporary work platform.

Personnal Fall Arrest Systems with limited freefall should be favored. For example working with an anchor point located directly above the head and using a self-retracting lifeline rather than working with a shock absorbing lanyard connected at foot level.

HOW TO PUT ON A HARNESS

STEP 1 - PREPARATION

Empty your pockets, in case of fall the

smallest object can injure you.

Inspect your harness : control its condition and find the dorsal D-ring.

STEP 2 - SHOULDER STRAPS

Grab your harness by the dorsal D-ring

and detangle the straps. If any of your

buckles are buckled, unbuckle them.

Make sure the webbings are not twisted and slip the straps over your shoulders like a jacket.

STEP 3 - CHEST STRAP

Close the chest strap buckles and adjust.

STEP 4 - LEG STRAPS

Pull the straps between the legs and connect. Tighten and adjust so that you can slip your hand but not

your fist.

STEP 5 - ADJUSTING

Reajust shoulder and leg straps. Pass

excess webbing through the keepers.

Adusting your harness to a snug fit will

avoid injury in the event of a fall. The

harness should allow free movements but not be loose. The dorsal D-ring shall be located between the shoulder blades.

The position of the dorsal D-ring

or chest strap can be adjusted up or down by sliding the dorsal plate on the webbing.

THE DIFFERENT ATTACHMENT POINTS ON A HARNESS

FALL FACTOR

CLEARANCE DISTANCE

SWING FALL

Swing falls or pendulum type falls occur when the anchorage point is not directly above the worker when the fall occurs. The force of striking an object or nearby structure while swinging can lead to serious injury.

SUSPENSION TRAUMA

DESCRIPTION

Even well equipped and trained, a worker at height still faces a significant risk after his fall has been arrested.

Without a quick rescue, he will soon face an orthostatic shock, more commonly known as suspension trauma or harness hang syndrome.

The thigh straps compress the veins, causing blood to pool in the legs. Such compression reduces the flow of oxygenated blood to his heart, kidneys and brain.

Although each individual reacts differently, studies show that prolonged suspension in a harness and lack of movement can result in loss of

consciousness within few minutes and death within 30 minutes if not adequately handled.

That's why suspension trauma is an absolute medical emergency.

FIRST SYMPTOMS

feeling of unease, sweating, nausea, dizziness and an increased pulse rate.

AGGRAVATING FACTORS

known history of heart disease, dehydration, hypothermia, exhaustion, immobility.

SOLUTION

To avoid suspension trauma and allow time for the rescue plan to be put in place, use Suspension Trauma Straps.

DROPPED OBJECT HAZARDS

An industrial helmet is tested for shock absorption and puncture but offers little protection against the risk of falling objects.

- The impact generated by a dropped tool is considerable.

- Tools don't fall only on your head!

- Objects can bounce, it is impossible to predict their trajectory, and therefore to delimit risk areas.

CONSÉQUENCE D'UNE CHUTE D'OBJET:

In accordance with the hierarchy of safety controls, IT IS ESSENTIAL TO SECURE YOUR TOOLS to prevent them from falling, rather than trying to limit their consequences.

Dropped objects rank in the top 3 of injuries on a job site.

SOLUTION

Don't rely only on your safety helmet to protect you from dropped objects, TETHER YOUR TOOLS! Use tool lanyards.

CLEANING, INSPECTIONS AND MAINTENANCE

CLEANING, MAINTENANCE AND STORAGE

- STORAGE

The storage location should be a cool, dry, and clean environment, out of direct sunlight; a locker or tool crib is recommended. Protective bags that come with the equipment should be used.

- CLEANING

Excess grease, dirt and grime should be removed. Most soft and hardware can be washed with mild soap, water, and a rag. The equipment should be dried with a rag and left to hang, out of direct sunlight.

IN CASE OF FALL

After a fall, systematically dispose of ALL PPE of the system and inspect the anchor in the case of a fixed anchor or a permanent lifeline. Some equipment, such as self retracting lifelines can be repaired by a maintenance center approved by the manufacturer.

MAINTENANCE

While textile equipment such as harnesses, lanyards, ropes, or metal products such as connectors/karabiners cannot be repaired, mechanical devices and some products can be serviced to ensure optimum performance and can be repaired. Fall Protection equipment should not be taken apart, modified or repaired in-house. Additional servicing should only be performed by factory authorized centers.

- Self Retracting Lifelines in cable or webbing above 6m

- Tripods

- Winches

Contact us for the maintenance or repair of your mechanical fall arresters

INSPECTIONS

A) PRE-USE CHECK

All fall protection equipment should be inspected by the user prior to each use for wear, damage and other deterioration.

If there is any doubt about the condition of PPE, refer to a competent person and if in doubt, discard it.

B) PERIODIC INSPECTION

WHY? The regulation

Personal Protective Equipment against falls from height must be checked periodically every twelve months at the maximum, in accordance with the EN365 standard "Personal protective equipment against falls from a height. General requirements for instructions for use, maintenance, periodic examination, repair, marking and packaging". This is also one of our manufacturer requirements.

This is an obligation of the user.

WHAT? Products to be inspected

ALL Personal Fall Protective Equipment is subject to a mandatory inspection, so all Coverguard fall protection items are concerned: Full body harnesses - Lanyards - Rope grabs - Webbing or cable retractable fall arresters - Connectors and karabiners - Anchors - Tripods and winches for confined spaces

WHEN? The frequency

At least once each twelve months. The 12 month period runs from the date of first use of the equipment, which must be recorded in the safety register. If there is no record of the date of first use in the safety register, the date of purchase or date of manufacture would be taken into account. This control is documented and recorded.

We recommend to have your Personal Fall Protective Equipment inspected at the slightest doubt and after intensive use.

WHO? A competent person

According to EN365: "A person who is aware of current requirements for periodic inspection, of the manufacturer’s recommendations and instructions issued for the relevant component, subsystem or system." We carry out the verification of our Fall Protection equipment, contact your Coverguard representative !

THE DIFFERENT FALL PROTECTION SYSTEMS

WORK RESTRAINT

A restraint system is designed to eliminate the risk of falling by restricting the user's movements to prevent him from reaching an area where there is a risk of falling. The length of the lanyard and the location of the anchorage point should be determined in such a way that the user cannot reach the risk area.

This system is the safest of the below exposed systems for obvious reasons: if the possibility of a

fall has been eliminated, the risk of serious injury and need for rescue has also been eliminated.

It is important to make sure that the fall restraint system is effectively limiting the travel of the worker to another point, where the potential for a fall exists.

FALL ARREST

Unlike Fall Restraint, a Fall Arrest system will not prevent a fall from occurring, and is designed to stop

the worker from striking the level below and minimize injury during the arrest of a fall.

It consists of an anchor, a full body harness and a connecting element limiting the forces in the body

(energy absorber), connected to the harness by an "A" marked attachment point.

Before using a fall arrest system, you should consider a rescue plan to retrieve the person after the fall.

WORK POSITIONING

Positioning systems are used for work at height where hands-free operations are required but excessive

movement is not necessary, typically when working on vertical structures like pylons.

The work positioning system should include a backup system, so that the fall can be arrested in case of error of the worker or failure of the primary support.

WORK IN SUSPENSION / ROPE ACCESS

Technique used to get person in suspension on ropes into areas that are hard to reach by other means e.g. abseiling, climbing on cliff faces, down caves or up in trees.

Example : window cleaning on facades where collective protection can’t be implemented

WORK IN CONFINED SPACE

Systems to safely enter in confined space such as tanks, manholes, silos, hatches etc.

The worker is secured from fall while descending into the confined space, and can be easily and quickly retrieved by a second operator by means of a winch if necessary.

A confined space system typically consists in a tripod,

self retracting lifeline and rescue winch.