STANDARDS

PPE Category:

The Regulation (EU) 2016/425 on personal protective equipments (PPE) defined the 3 PPE types as follows :

- Category I : includes exclusively the following minimal risks: superficial mechanical injury; contact with cleaning materials of weak action or prolonged contact with water; contact with hot surfaces not exceeding 50°C; damage to the eyes due to exposure to sunlight (other than during observation of the sun); atmospheric conditions that are not of an extreme nature. Manufacturer is allowed to test and self-certify products.

- Category II : includes risks other than those listed in Categories I and III. Manufacturer must obtain a EU certificate of conformity from a notified body.

- Category III : includes exclusively the risks that may cause very serious consequences such as death or irreversible damage to health relating to the following: substances and mixtures which are hazardous to health; atmospheres with oxygen deficiency; harmful biological agents; ionising radiation; high-temperature environments the effects of which are comparable to those of an air temperature of at least 100°C; low-temperature environments the effects of which are comparable to those of an air temperature of -50°C or less; falling from a height; electric shock and live working; drowning; cuts by hand-held chainsaws; high-pressure jets; bullet wounds or knife stabs; harmful noise. Manufacturer must obtain a EU certificate of conformity and certificates of regular production monitoring from notified bodies.

STANDARDS

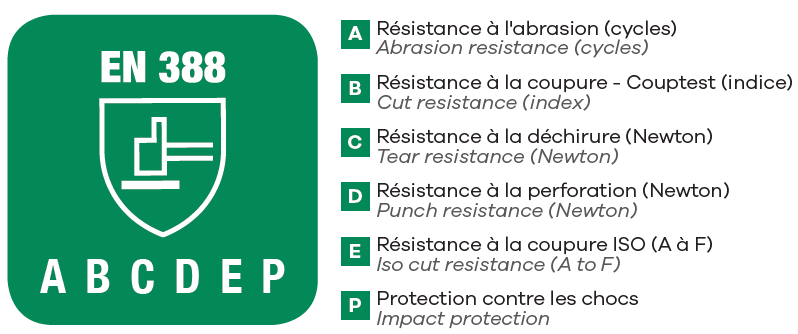

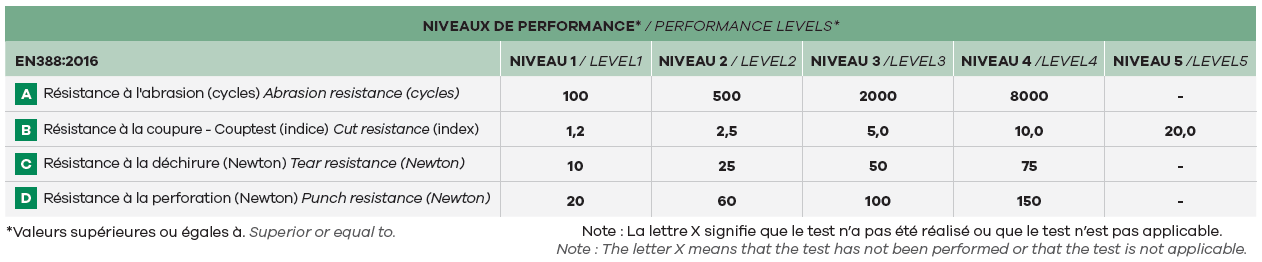

EN 388 STANDARD

Standard EN 388 applies to mechanical risks.

It defines the performance standards for abrasion, cutting, tearing, perforation as well as the impact resistance.

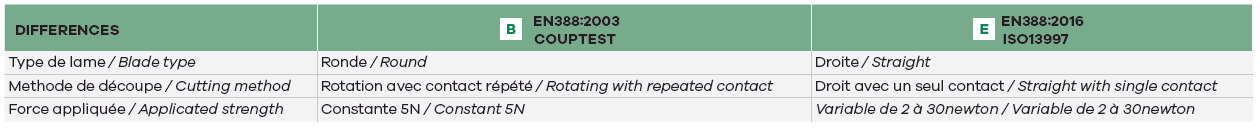

Main differences between the 2 cut-tests provided for by the EN388 standard, the Coupe-test and the TDM :

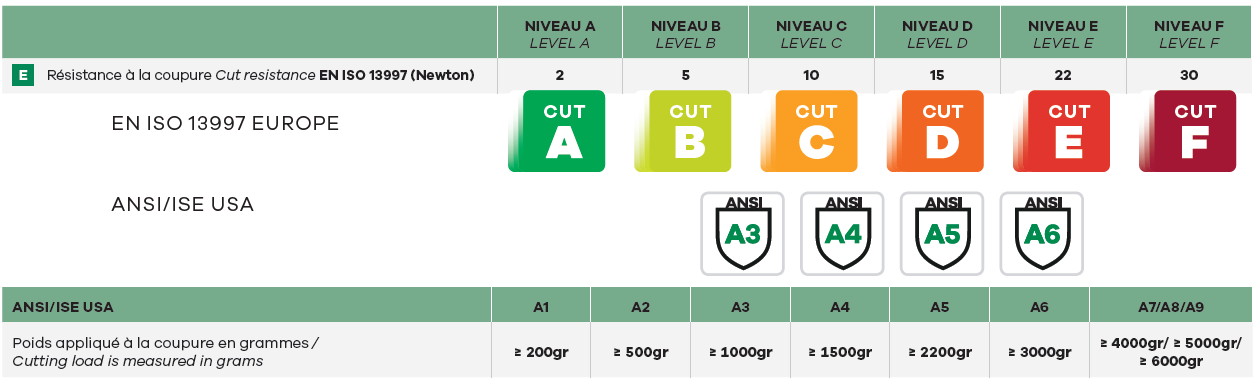

Correlation between TDM and ANSI performance :

EN 13594: 2015 STANDARD

A new optional test is introduced to meet the requirements of the impact test according to the EN 13594: 2015 standard. To pass the test, the mean transmitted force needs to be less than or equal to 7 kN with no single results greater than 9 kN. In the case where the glove passes the test, the letter P can be added at the end of the marking under the pictogram.

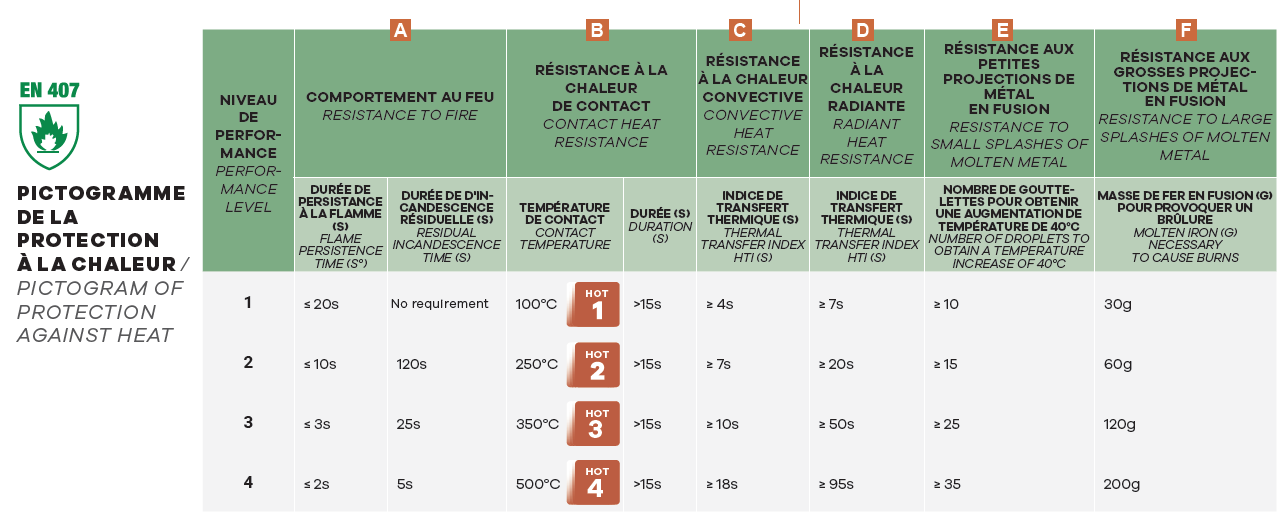

EN 407 STANDARD

EN 511 STANDARD

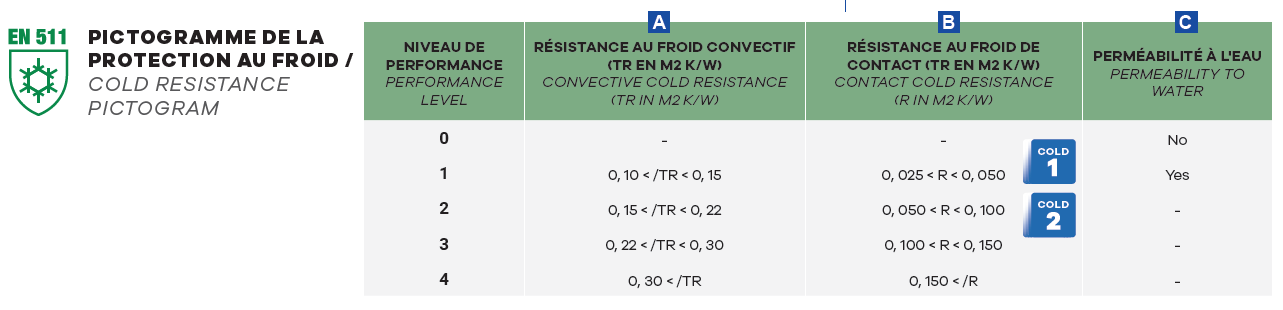

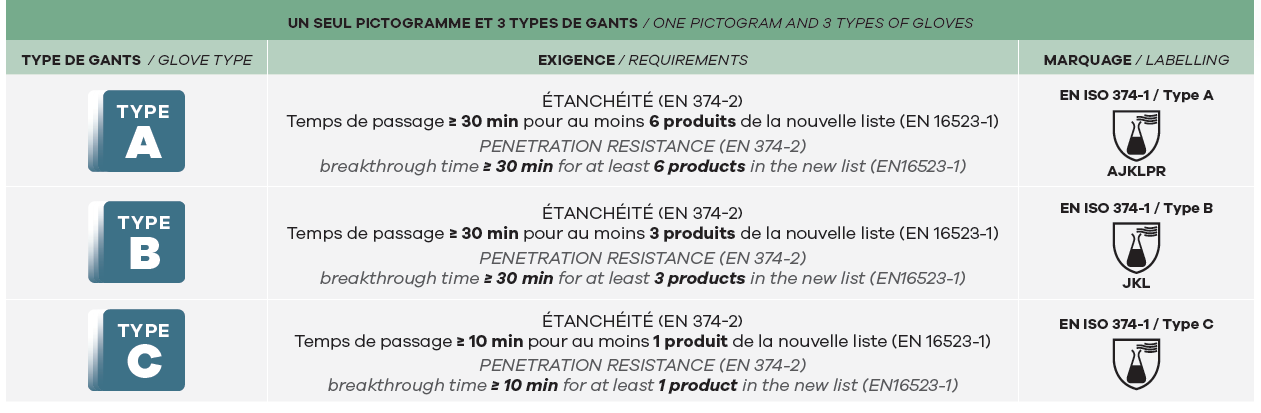

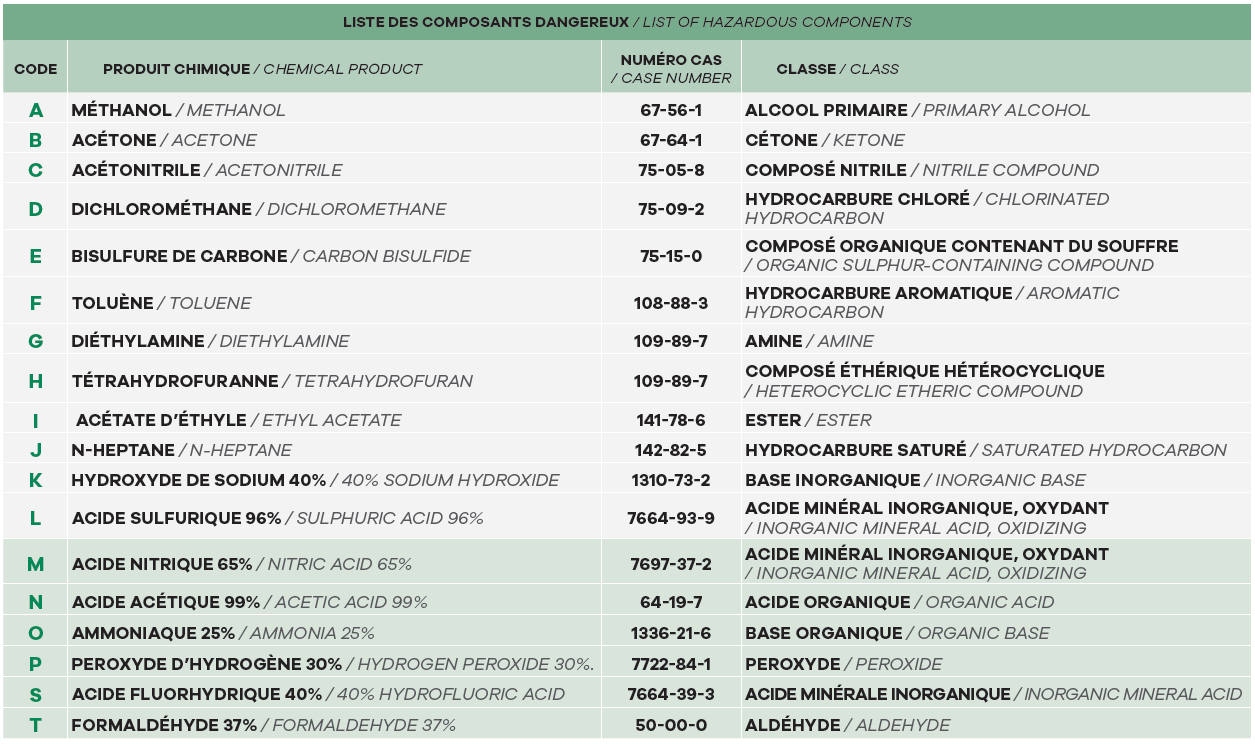

EN 374 STANDARD

DEGRADATION TEST

In order to be able to claim protection against a chemical on the list, permeation as well as degradation tests must be carried out. The result of the degradation test is reported in the information leaflet.

EN 374-5 : 2016 STANDARD

The gloves must pass the penetration resistance test standard EN374-2:2014. The possibility of claiming protection against viruses has been added if the glove passes the ISO 16604 test: 2004 (method B) test

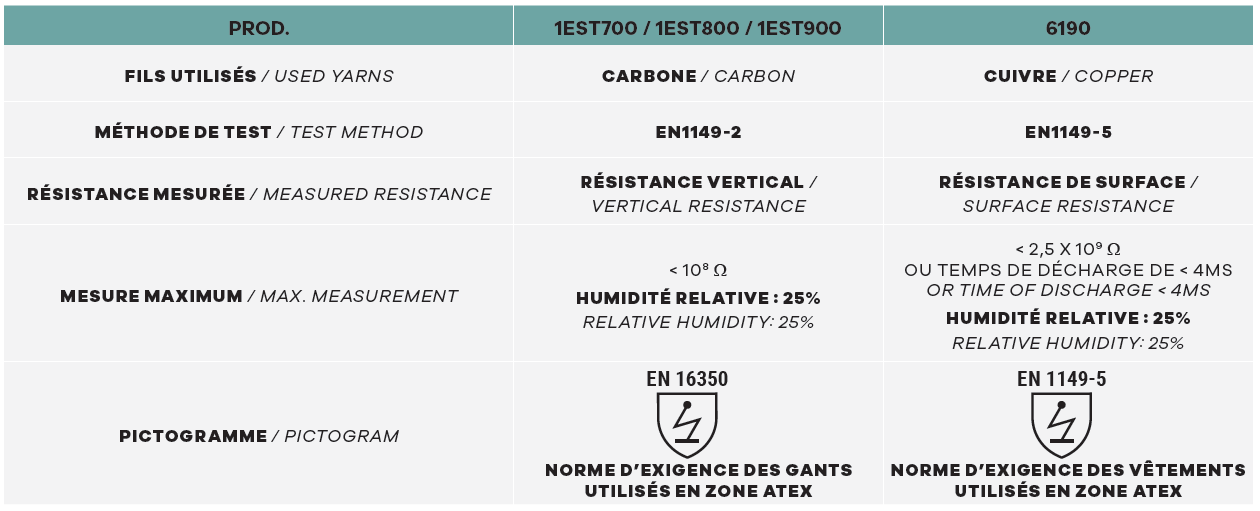

ELECTROSTATIC DISCHARGE - ESD

Working in explosive areas (ATEX zones) or assembling electronic devices, needs the use of gloves with electrostatic charge dissipation properties.

Currently, there are no standards for ESD glove. As the ATEX standard is very restrictive on the explosive risks related to electrical discharges it is usually associated with the measurement of electrostatic dissipation.

EN 60903:2003 - INSULATING GLOVES FOR LIVE WORKING

Insulating gloves for live working complies with the specifications of the European standard EN 60903:2003 and the international standard IEC 60903:2014.

ln the choice of class, it is important to define the network nominal voltage which must not exceed the maximum operating voltage. For multiphase networks, the network nominal voltage is the voltage between phases.

The test voltage is the one applied to gloves during the individual routine tests.

PERIODIC INSPECTION :

Our insulating gloves have no expiry date and can be used as long as they pass periodic inspections recommended by IEC 60903. We recommend testing gloves in service every six months and gloves in stock every 12 months; the recommended method of testing is visual inspection and dielectric testing. More information are available on the instructions for use.

RECOMMENDATIONS BEFORE USE :

Full visual inspection of each glove must be done before each use. Use a manual air pressure device for testing the glove by inflating it and thus detecting any defects. If a glove is defective, both the gloves of the pair must be rejected from use and checked by a trained person.

STANDARDS

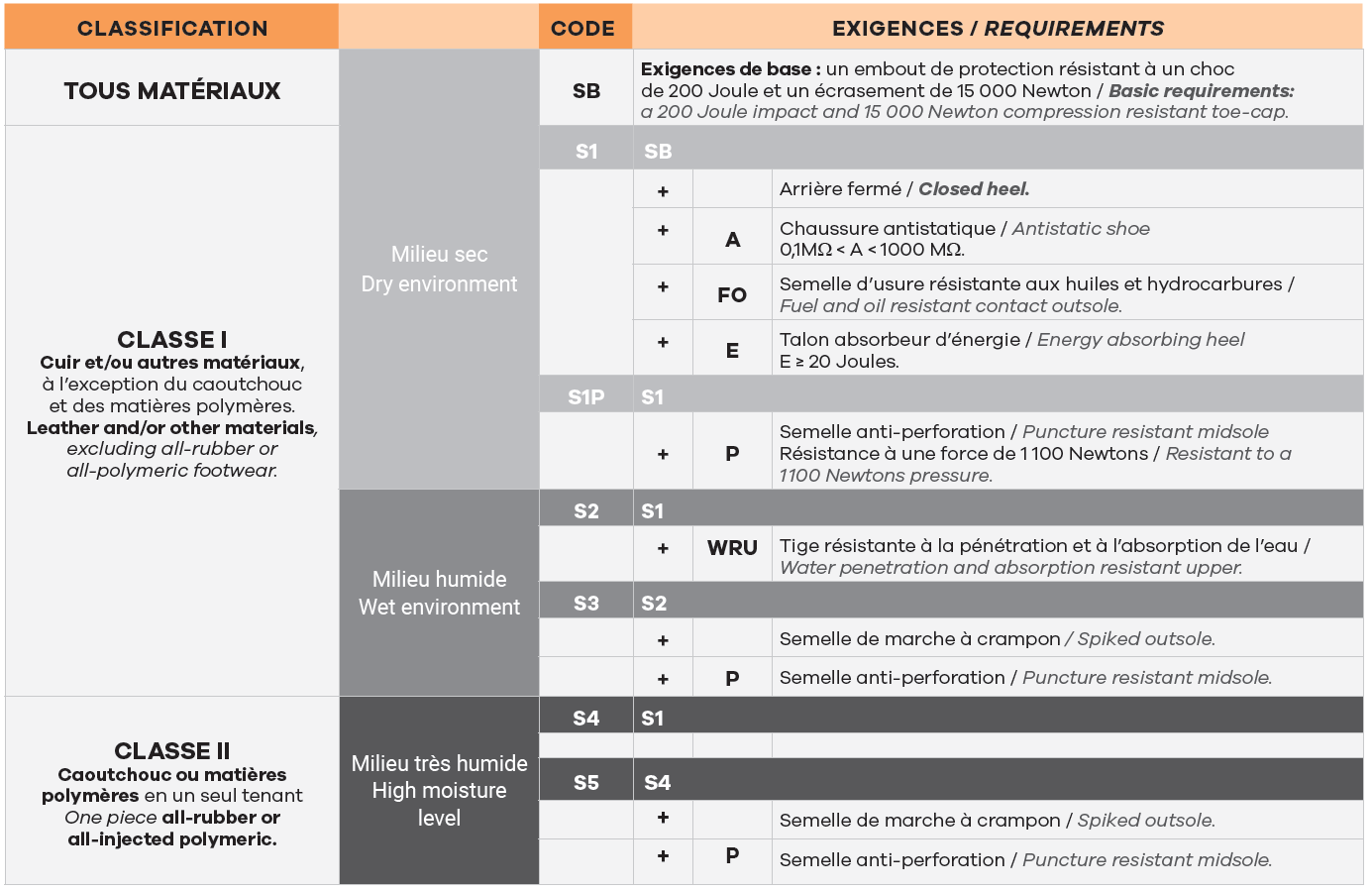

EN ISO 20345 : 2011

This standard specifies basic (SB) and additional/optional (S1 to S5) requirements for safety footwear used for general purpose.

It includes, for example, mechanical risks, slip resistance, thermal risks and ergonomic behavior.

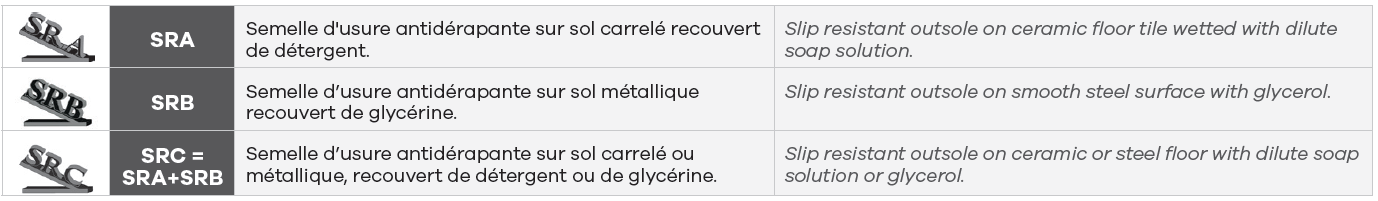

SLIP RESISTANCE

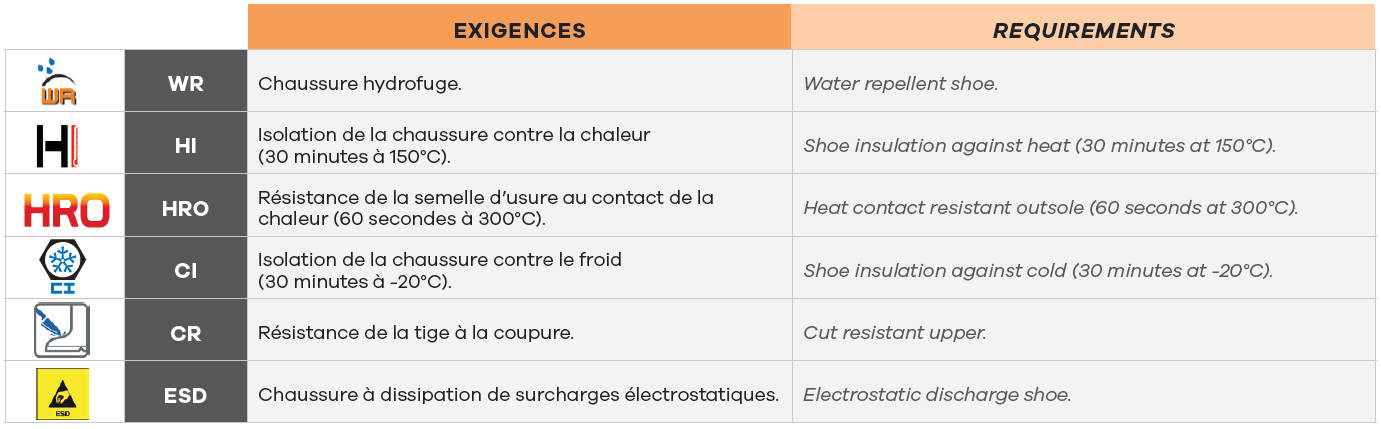

ADDITIONAL STANDARDS

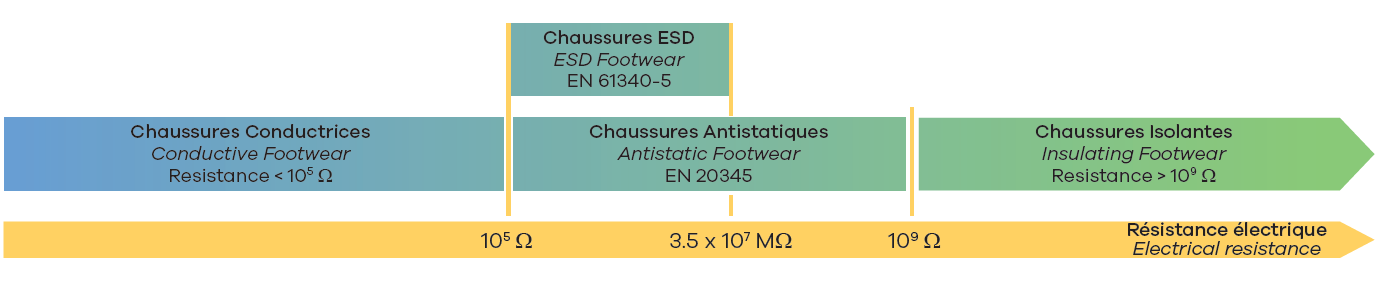

ANTISTATIC & ESD FOOTWEAR

For some industries the risk of uncontrolled electrical discharge (sparks) in potentially explosive atmospheres or the protection of sensitive devices are very important considerations.

In these situations, a standard for Electro-Static Discharge (ESD) control applies: EN 61340-5-1. The minimal electrical resistance of a ESD shoe is 100 kΩ (the same as for antistatic footwear) and the upper limit is 35 MΩ (3.5 x 107 ohms).

This means that ESD compliant shoe is also antistatic, by definition.

ELECTRICAL RESISTANCES AND ESD (ELECTRO-STATIC DISCHARGE) VALUES

STANDARDS

EN ISO 13688 - PROTECTIVE CLOTHING : GENERAL REQUIREMENT

This standard fulfils the essential requirements of the regulation : Ergonomics / Comfort / Innocuity / Compatibility of garments with other equipment or worn as a set / Durability, ageing / Marking and information notice / Indication of the wearer’s size.

It cannot be used alone but only in combination with other standards.

NF EN 14058 : 2017 - PROTECTION AGAINST COOL ENVIRONMENTS

Standard NF EN 14058 specifies the requirements and test methods relating to the performance of protective clothing against moderately cold environments. A cool climate is the combination of humid and windy conditions at an air temperature of -5°C and above.

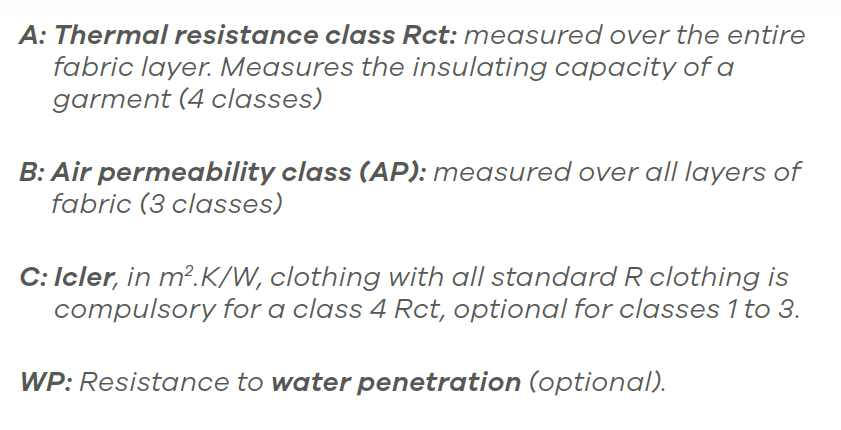

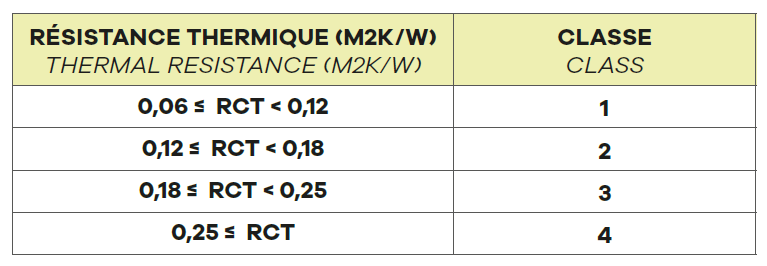

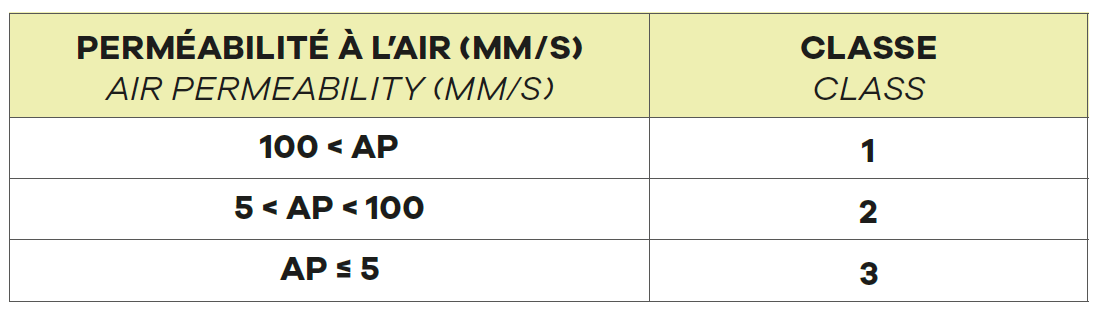

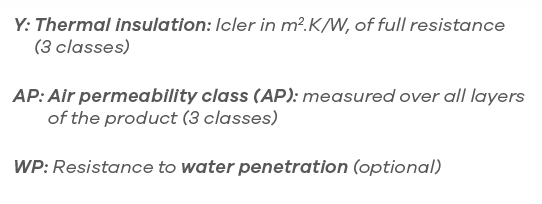

The EN 14058 standard takes into account several types of performance indices:

NF EN 342 : 2017 - GARMENTS FOR PROTECTION AGAINST COLD

The NF EN 342 standard specifies the requirements and test methods on the performance of protective clothing against the effects of cold environments at temperatures below -5°C, also mixing wind and humidity.

The standard distinguishes three essential characteristics:

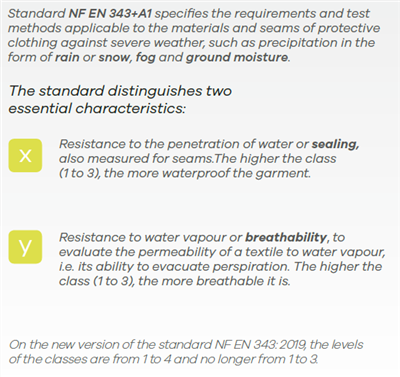

NF EN 343+A1 : 2007 - RAIN PROTECTION

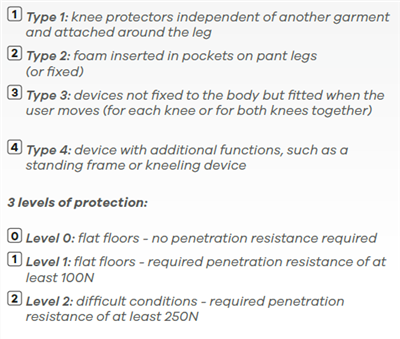

EN 14404 + A1 - RELATING ON KNEE PROTECTION

ISO 20471 - WARNING CLOTHING HI-VISIBILITY

The EN ISO 20471 standard specifies the requirements that High Visibility garments must comply with in order to visually signal the presence of the user, particularly in conditions of dangerous, day and night.

Many professionals may be concerned about wearing high-visibility clothing.

The use of signal clothing conforming to EN ISO 20471 is:

- compulsory according to the wearer’s working conditions (e.g. on roadsides, in different types of transport (road, rail), on airport runways)

- highly recommended (e.g. :on building sites, forklift operators)

Fluorescent fabric :allows daytime visibility. It reacts under the radiation of natural light and transforms part of the non-visible light (UV) into visible light.

3 approved colours :yellow, orange and red, creating a contrast with the natural environment.

Retro-reflective material :allows visibility at night. It reflects a maximum amount of light back to its source (vehicle headlights)

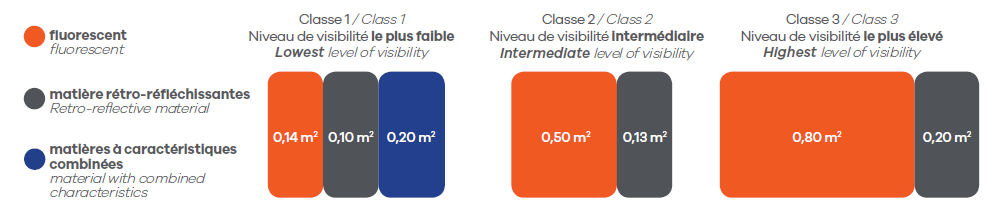

The standard distinguishes between 3 classes (X):Depending on the minimum surface areas of fluorescent and retro-reflective materials for the 3 classes, plus materials with combined characteristics (only for class 1)

A garment only covering the torso (bib, vest)or covering the torso and arms (coat, jacket, T-shirt, etc.) must at least have a retro-reflective "belt" stripe, supplemented either by a second "belt" stripe, or by two "strap" stripes. If a sleeve prevents from distinguishing one (two) stripe(s) on torso, thesleeve must be surrounded by one (or two) "armband" stripes.If it is a long sleeve, it must be surrounded by two "armband" stripes. Clothing covering the legs must have at least two stripes around each leg.

Class 3 clothing must necessarily cover the torso and have sleeves and/

or long legs with retro-reflective stripes. At least (50 ± 10)% of the minimum visible base material area shall be at the front of the garment. A test on colour fastness (fluorescent and dark) for washing, dry cleaning, bleaching and/or ironing and another on water vapour resistance are also required for certification.

CLOTHING CLASS RECOMMENDED ACCORDING TO RISK

* Passive: person on the road not taking part and concentrating on something other than traffic, such as a road worker or a person in an emergency situation.

Active: person on the road taking part and concentrating on the traffic, such as a cyclist or pedestrian moving on the road.

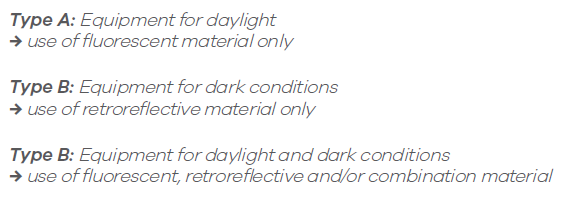

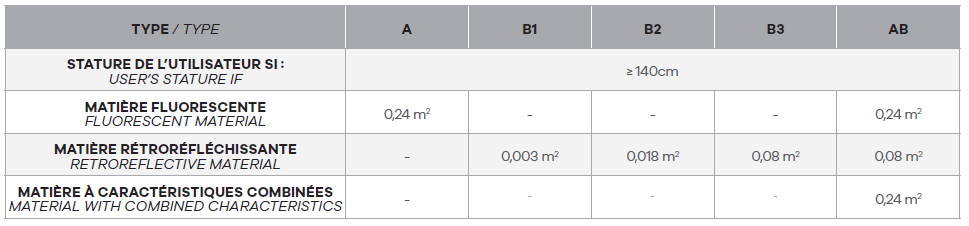

EN 17353 : 2020 - ENHANCES VISIBILITY EQUIPMENT FOR MEDIUM RISK SITUATIONS

The EN 17353 standard specifies the requirements for enhanced visualization equipment to make the user’s presence more perceptible, especially in situations of moderate light/lighting risk, both day and night.

IDENTIFIER LA PROTECTION RESPIRATOIRE APPROPRIÉE À SON USAGE

RESPIRATORY RISKS ASSESSMENT

Amending Directive 2004/37/EC, Directive (EU) 2019/983, which comes into force in July 2021 , provides for a lowering of the exposure limit values for certain carcinogens or mutagens at work. It sets out a framework of general principles to enable Member States to apply the minimum requirements uniformly In addition, Directive 2004/37/EC does not prevent Member States from applying additional measures, such as a biological limit value.

The European Standard EN 529:2005 shows how to select the correct breathing equipments based on the risk assessment. This standard indicates the “protection factor” which is by definition the parameter that expresses the ratio between the concentration of the contaminant in the environment and its concentration inside the breathing equipment. An important distinction concerns the nominal protection factor (NPF) and the assigned protection factor (APF).

The nominal protection factor (NPF) is a number derived from the maximum percentage of total loss (towards the inside of the breathing equipment) allowed by European standards.

The assigned protection factor (APF) is the level of respiratory protection that one can realistically expect in the workplace by 95% of the PPE users.

Furthermore , an important reference for choosing the breathing equipment is the Threshold Limit Value (TLV), or rather the “exposure limit value”, which indicates the environmental concentrations of airborne chemicals below which most workers can remain repeatedly exposed to day after day for their working life without any negative effect on their health.

STANDARDS

MARKING DESCRIPTION

PERFORMANCE LEVEL OF GAS FILTERS

To wear a face mask like a full face or a half face mask, it is necessary to make sure that the sealing surface is completely continuous to the face.

Men must be correctly shaved and any interposition of hair, beard, or glasses temples must be avoided (otherwise the assigned protection factor will be reduced).

FILTERS OF MARKS WITH CARTRIDGES

GAS FILTERS

Protect from gases and toxic vapors.

LONGEVITY TEST OF A GAS FILTER

The longevity of a gas filter is measured by outputting trial gas up to 30 L/min, it means that the volume of air an average-build person breathes per minute, while doing an average-tough work. The longevity can also Roughly be calculated bringing the concentration in-site with the minimum penetration time that is required for one type of filter.

ANTI-GAS FILTER LONGEVITY CALCULATION

DOMAINE D’UTILISATION

A

Gases and vapors of organic compounds at boiling point > 65 °C.

Examples of specific hydrocarbons: toluene, benzene, xylene, styrene, turpentine, cyclohexane, carbon tetrachloride, trichloroethylene. Some solvents are often used in the form of mixtures, for instance Solvents from benzene, mineral essence, mineral turpentine, white spirit, naphtha solvent. Other organic compounds: dimethylformamide, phenol, furfuryl alcohol, diacetone alcohol. As well as some raw materials raw materials and plastic additives, such as phthalates, phenolic resins, epoxidic plastics and polychlorobiphenyls in the form of PCB isomers.

AX

Gases and vapours of organic compounds at boiling point < 65 °C

B

Inorganic gases and vapours

For example: sulphide dioxide, chlorine, hydrogen sulphide (H2S), hydrogen cyanide (HCN), hydrochloric gas (HCI), cyanide compounds, phosphorus and phosphoric acid.

E

Organic acids, acid gases and in general gaseous acids, nitric acid, propionic acid, formic acid.

K

Ammonia and its organic derivatives organic amino such as methylamine, ethylamine, ethylenediamine,

diethylamide.

P

Particles, solid and liquid aerosols

HG

Mercury

NO

Nitrous vapors and vitrogen dioxide

CO

Carbon monoxide

NORMES

Our tests and certificates are based on applicable standards:

- USA : ANSI Z87:1

- EUROPE : CE EN166:2001

- AUSTRALIE : AS/NZS1337 / AUSTRALIA : AS/NZS1337

- JAPON : JIS T 8147 / JAPAN : JIS T 8147

- CANADA : CSA Z94

SOLAR PROTECTIONS THAT FILTER UV-A AND UV-B

Even on cloudy days, UV protection is essential because clouds absorb visible light, but very little UV.

The eyes are even more exposed when we are in mountains or in environments where UV are reflected by snow, water, sand, reverberation from light-coloured walls, windows or mirrors (e.g.: water reflects 5 to 10% of UV; sand 20%; snow 85%). Furthermore, in mountains, the quantity of received UV increases by 10% every 1000 meters. This is why all Coverguard safety glasses provide 99,9% UV protection.

CATEGORISATION OF SUNGLASSES ACCORDING TO THE EUROPEAN STANDARD EN12312-1

STANDARDS

The individual noise protectors are classified in the category III of individual protectors.

This category includes equipments which are used against irreversible or fatal sores.

FIND THE APPROPRIATE HEARING PROTECTION

Following parameters have to be considered:

- Identification of the nature of noise: stable, fluctuating, intermittent , pulse

- Measurement of the noise at workplace: Intensity (dB) and volume (Hz)

- Definition of the exposure time

- Calculation of the reduction level needed

EMPLOYER'S DUTIES

In the workplace, the noise exposure limit values , which must not be exceeded, principally pertains to a daily or weekly exposure of 87 decibels (dB), taking into account any attenuation from hearing protection.

The exposure action values , the decibel level at which an employer must take certain actions, are set at a daily or weekly exposure of 80 dB (lower value) and 85 dB (upper value).

MINIMUM REQUIREMENT RELATIVE TO NOISE PROTECTION AT WORKPLACE

dB(A) = It is an A weighted decibel which is a unit of sound pressure level to measure environmental noise. Sound level meters are programmed to measure dBA, with «A» being a factor applied to reflect how the human ear would hear and interpret the sound being measured.

MARKING DESCRIPTION

HOW TO READ ATTENUATION INDEX AND VALUES

SPECIFIC APPLICATIONS TO FOOD INDUSTRY

People working in food industry have special needs :

- Good hearing protection

- Earplugs can be tracked if dropped in food preparations.

The earplugs 30210, 30211 and 30212 have a stainless steel ball diameter 2.75 mm) inside the stem.

It allows trailing the earplug with a metal detector. The earplugs are blue, the only colour that cannot be found in food .

STANDARDS

STANDARDS REQUIREMENTS FOR SKULL PROTECTION

DISTINCTIVE PERFORMANCES FOR SPECIFIC USES

PROTECTION LEVEL

LOW LEVEL OF PROTECTION

HIGH LEVEL OF PROTECTION

TYPE 6

Limited liquid chemical products protection

TYPE 5

Chemical particles protection

TYPE 4

Particletight

TYPE 3

Watertight

TYPE 2

Limited gaztightness

TYPE 1

Gaztight

STANDARDS

Before any use, a risk analysis must be carried out by a health and safety expert.

He will take into account the types of exposures with which the worker may be confronted (solid and liquid chemicals, gases, infectious agents, radioactive particles, ATEX zone, etc...).

Chemical performances

Mechanical performances

PRINCIPES GÉNÉRAUX DU TRAVAIL EN HAUTEUR

When we talk about Fall Protection, the image that often comes to mind is a worker using a full body harness, ie a Personal Fall Arrest System (PFAS).

This is actually the last method to consider when you plan work at height. Your first step should be trying to eliminate the fall hazard altogether.

AVOID work at height –– (also called engineering out the hazard) meaning working as much as possible from the ground, using extending tools instead of a ladder, lowering something to ground level before repairing it, or for example using drones to get high vantage points.

This can require modifying the work process or work area to eliminate the need to work at height.

PREVENT a fall using Collective Fall Prevention systems collective fall prevention systems such as guardrails, handrails, ladder cages, mobile elevating work platforms (MEWP)...

PREVENT a fall using Personal Fall Prevention systems fall restraint systems, to prevent people getting close to an unprotected area

The logic of the hierarchy of controls favours permanent rather than temporary equipment in collective protection. Similarly, CPE take precedence over PPE.

MINIMIZE consequences of a fall (Fall Arrest)– with a Personnal Fall Arrest Systems using a harness, energy absorbing lanyard and anchor point to minimise the risks and consequencs of a fall (especially the arresting force).

Fall arrest equipment will not prevent a fall from occurring and Personnal Fall Arrest systems are therefore the least preferred methods of working at height.

They should be used in situations where it is not practicable to arrange for the work to be done from a more suited surface, such as fixed or temporary work platform.

Personnal Fall Arrest Systems with limited freefall should be favored. For example working with an anchor point located directly above the head and using a self-retracting lifeline rather than working with a shock absorbing lanyard connected at foot level.

STANDARDS

EN 341: DESCENDER DEVICES FOR RESCUE

EN 353: GUIDED TYPE FALL ARRESTERS

- EN 353-1: including a rigid anchor line

- EN 353-2: including a flexible anchor line

EN 354: LANYARDS

EN 355: ENERGY ABSORBERS

EN 358: BELTS AND LANYARDS FOR WORK POSITIONING OR RESTRAINT

EN 360: RETRACTABLE TYPE FALL ARRESTERS

EN 361: FULL BODY HARNESSES

EN 362: CONNECTORS

EN 363: PERSONAL FALL PROTECTION SYSTEMS

EN 364: TEST METHODS

EN 365: GENERAL REQUIREMENTS FOR INSTRUCTIONS FOR USE, MAINTENANCE, PERIODIC EXAMINATION, REPAIR, MARKING & PACKAGING

EN 397: INDUSTRIAL SAFETY HELMETS

EN 795: ANCHOR DEVICES

- Class A : Structural anchors

- Class B :Transportable temporary anchor devices (CE)

- Class C :Anchor devices employing horizontal flexible lines

- Class D :Anchor devices employing horizontal rigid anchor rails

- Class E :Dead weight anchors (CE)

EN 813: SIT HARNESSES

EN 1496: RESCUE LIFTING DEVICES

EN 1497: RESCUE HARNESSES

EN 1498: RESCUE LOOPS

EN 12278: PULLEYS

CLEANING, INSPECTIONS AND MAINTENANCE

CLEANING, MAINTENANCE AND STORAGE

- STORAGE

The storage location should be a cool, dry, and clean environment, out of direct sunlight; a locker or tool crib is recommended. Protective bags that come with the equipment should be used.

- CLEANING

Excess grease, dirt and grime should be removed. Most soft and hardware can be washed with mild soap, water, and a rag. The equipment should be dried with a rag and left to hang, out of direct sunlight.

IN CASE OF FALL

After a fall, systematically dispose of ALL PPE of the system and inspect the anchor in the case of a fixed anchor or a permanent lifeline. Some equipment, such as self retracting lifelines can be repaired by a maintenance center approved by the manufacturer.

MAINTENANCE

While textile equipment such as harnesses, lanyards, ropes, or metal products such as connectors/karabiners cannot be repaired, mechanical devices and some products can be serviced to ensure optimum performance and can be repaired.

Fall Protection equipment should not be taken apart, modified or repaired in-house. Additional servicing should only be performed by factory authorized centers.

- Self Retracting Lifelines in cable or webbing above 6 m

- Tripods

- Winches

Contact us for the maintenance or repair of your mechanical fall arresters

INSPECTIONS

A) PRE-USE CHECK

All fall protection equipment should be inspected by the user prior to each use for wear, damage and other deterioration.

If there is any doubt about the condition of PPE, refer to a competent person and if in doubt, discard it.

B) PERIODIC INSPECTION

WHY? The regulation

Personal Protective Equipment against falls from height must be checked periodically every twelve months at the maximum, in accordance with the EN365 standard "Personal protective equipment against falls from a height. General requirements for instructions for use, maintenance, periodic examination, repair, marking and packaging". This is also one of our manufacturer requirements.

This is an obligation of the user.

WHAT? Products to be inspected

ALL Personal Fall Protective Equipment is subject to a mandatory inspection, so all Coverguard fall protection items are concerned: Full body harnesses - Lanyards - Rope grabs - Webbing or cable retractable fall arresters - Connectors and karabiners - Anchors - Tripods and winches for confined spaces

WHEN? The frequency

At least once each twelve months. The 12 month period runs from the date of first use of the equipment, which must be recorded in the safety register. If there is no record of the date of first use in the safety register, the date of purchase or date of manufacture would be taken into account. This control is documented and recorded.

We recommend to have your Personal Fall Protective Equipment inspected at the slightest doubt and after intensive use.

WHO? A competent person

According to EN365: "A person who is aware of current requirements for periodic inspection, of the manufacturer’s recommendations and instructions issued for the relevant component, subsystem or system." We carry out the verification of our Fall Protection equipment, contact your Coverguard representative !