How To Choose Your Cut Protection Glove?

Choosing the right anti-cutting glove can be a challenge because there is such a wide range of solutions.

M. Bottelé, CEO at EVAFLO says: "Due to the size of our company, we don't have Quality and Health Safety and Environment Officer so it's my responsibility to choose the right equipment, but there are so many models in the catalogues that it's sometimes difficult to find the right solution through all the standards and specificities." »

CUT RESISTANCE – EN 388:2016 Mechanical Standard

Let's first start with a brief explanation of EN388:2016 Standard, which frames the definition of mechanical protection in general and more specifically cut protection.

The EN 388 standard has 2 complementary test methods that evaluate cut resistance.

The first test, known as the "Couptest", is used to assess the resistance to a repetitive and prolonged but low intensity cut. This test is particularly useful for people who constantly handle small metal or glass parts: automotive industry, mechanics, etc.

How Does It Work?

The glove is subjected to a rotating and circular blade that exerts a constant force of 5N on the material, i.e. approximately 500g. This test measures the number of cycles until the material is cut and determines the performance of the material. A score of 1 out of 5 is then attributed to the tested material.

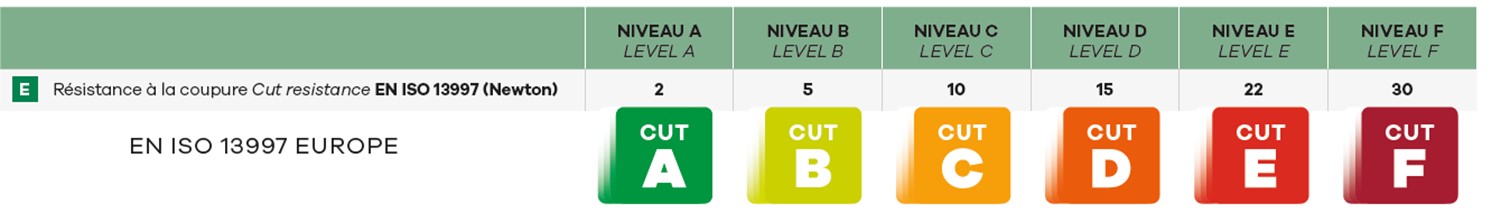

In 2016, the European standard incorporated a new test called the "TDM test" related to ISO 13997.

This test performed with a straight blade evaluates the resistance of a material to a short, dry cut with an applied force of varying intensity ranging from 2 to 30N. The "TDM test" is a good performance indicator for accidental risks such as blows from a cutter or accidents related to carrying sharp, heavy and slippery objects: glass or steel plates.

At the end of the "TDM test", a performance level from A to F is then assigned to the glove.

CHOOSING THE RIGHT CUT PROTECTION GLOVE :

According to Ingrid DOGER, Group Product Manager for gloves at Coverguard: "You have to keep in mind that there is no such thing as a universal glove that protects against all risks. It is therefore necessary to specify the need". To do this, we propose a methodology in 6 steps:

1 - IDENTIFY THE RISK INVOLVED: WHAT TYPE OF CUTS?

The first step is to define the type of cut to which the wearer is exposed:

- Fine handling, in the presence of light and sharp parts?

- Heavy handling, with sharp and heavy parts?

When the risk of accidental cuts is high, we recommend a CUT E or CUT F glove. These are generally gloves containing high density polymers (HDPE / HDPA) combined or not with mineral fibers such as glass fibers, steel wires, etc.

But often, the user does not perform only one task at his workstation. As he is exposed to various risks, it will then be necessary to provide :

- Either several protective solutions to guarantee his safety.

- Either a multi-purpose glove that combines cut and thermal protection in cold conditions: 1WIND00, cut and thermal protection in heat conditions: 1CUFF00, cut and waterproof protection: 1CRFN, etc.

2 - WHAT ENVIRONMENT?

It is then important to take into account the working environment to choose the most appropriate coating:

- For a dry environment: choose a PU glove that lets the hand breathe

- For a dry to oily environment: choose a nitrile coating which allows to keep the grip

- For a dry to wet environment: choose a latex coating which is waterproof and will keep the hand dry

3 - WHAT LEVEL OF COMFORT DO YOU WANT?

If the glove is to be worn for a long time, its comfort becomes essential. Its breathability and its capacity to absorb perspiration are essential criteria.

For permanent use: it becomes essential that the hand can breathe and that the glove does not exacerbate hand fatigue. A ¾ or palm coating is therefore to be preferred.

For short to intermittent use: waterproofing is favored over breathability because the glove will be worn for a short to medium duration. A full coating is therefore preferable.

4 – WHAT SIZE?

"The choice of size is just as important as for shoes. A glove that is too large will tend to slip and provide less precision in the gesture, not to mention the loss of productivity due to the multiple interruptions to adjust the glove. A glove that is too small will quickly become unpleasant to wear because it is too tight and will cause fatigue. The best thing to do is to try the glove on the workstation and above all, for buyers, not to give in to the temptation of a single size for all the company's operators", explains Ingrid DOGER.

5 - FOR WHAT COST OF USE?

The cost of use, which is different from the cost of purchase, takes into account the durability of the product. Is the product for single use? Can it be washed? Is it abrasion resistant?

Generally speaking, low-cost gloves - whether or not they offer the necessary protection - are more expensive in the long run because they have to be replaced more often.

6 - CHOOSE YOUR CUT RESISTANT GLOVE OPTIONS

Many of our anti-cut references do not only protect against cuts, but combine several other features: thumb and index finger reinforcement, long cuff, tactile properties, palm reinforcement, impact resistance, abrasion resistance, etc.

It will be necessary to define which of these options you consider essential to select your best ally!