Evolution of the EN 407:2020 Standard

Recently revised, the new EN407:2020 standard now includes all contact heat and flame protection gloves, arm protection devices as well as thermal protection items for consumer household use: kitchen gloves, barbecue gloves, potholders, etc.

This standard does not concern gloves for firemen (EN659), nor gloves for welders (EN12477).

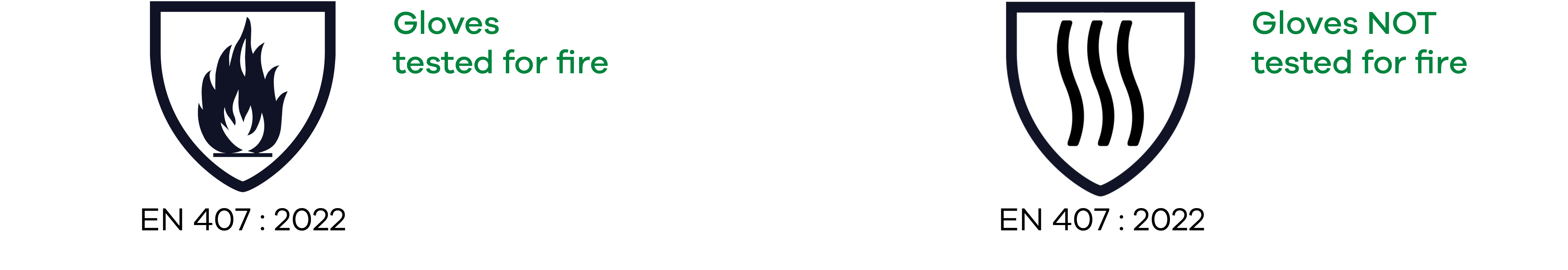

A new pictogram appears for non-flame resistant gloves:

NB: At the time of the revision of the standard, the performance levels have not changed and still go from level 1 to level 4. When the performance level is symbolized by the letter X, it means that the test has not been performed.

What is the EN407 standard?

The EN407 standard concerns protection against thermal risks. It is composed of 6 tests.

Under the pictograms of the flame and the heat we find 6 figures, representing the scores obtained during the tests.

Flammability resistance test

The glove is placed vertically over a burner and tested for ignition times of 3 and 15 seconds. Classification is based on the length of time the material continues to burn and glow after the ignition source has been removed.

Contact heat resistance test

The test sample is placed on a calorimeter and a heated cylinder is brought into contact with the sample.

Temperatures of 100°C, 250°C, 350°C and 500°C are tested to determine classification. The threshold time is calculated when an increase in calorimeter temperature of 10°C is observed once the heated cylinder is in contact with the sample. A threshold DE time greater than 15 seconds indicates a pass for the test temperature.

If a contact heat level 3 is achieved, the combustion behavior must also be tested and pass level 1.

Convective heat resistance test

The glove is placed in a controlled chamber and exposed to a flame. The resistance is based on the time it takes to transfer the heat from the flame. This rating can only be used if a level 3 or 4 is achieved in the fire behavior test.

Radiant heat resistance test

The glove is exposed to radiant heat and the classification is determined by the time it takes to transfer heat from the radiant heat source. The back of the hand is tested. This classification can only be used if a level 3 or 4 is achieved in the fire behavior test.

Test for resistance to small splashes of molten metal

The glove is splashed with molten metal and the number of drops of molten metal required to heat the glove to the required temperature is measured. Classification is based on the average number of droplets counted from four samples. The samples are taken from the palm and back of the glove. This classification can only be used if a level 3 or 4 is reached in the fire behavior test.

Test for resistance to large splashes of molten metal

The glove is lined with a material simulating the skin and molten metal is poured onto the glove. After the test, the liner material is evaluated for any changes, such as holes or degradation. The classification is based on the weight of molten metal required to cause the changes in the skin material. If a drop of molten metal sticks to the glove or if the sample ignites, the material fails the test.

NB: During the revision of the standard, some processes have evolved to improve the quality of the tests.

- Improved test methods to measure fire behavior, contact and convection heat resistance, large amounts of molten metal.

Performance levels are no longer based on the average but on the lowest test results

Introduction of a minimum mechanical strength: Level 1 (10N) minimum for tear resistance EN 388